Buflovak Atmospheric Drum Dryer

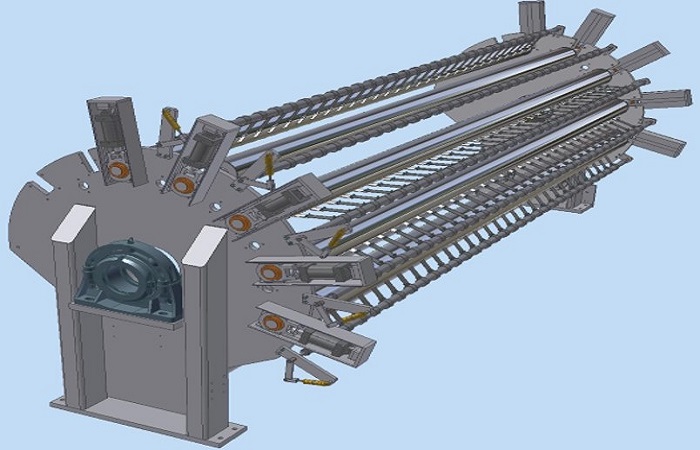

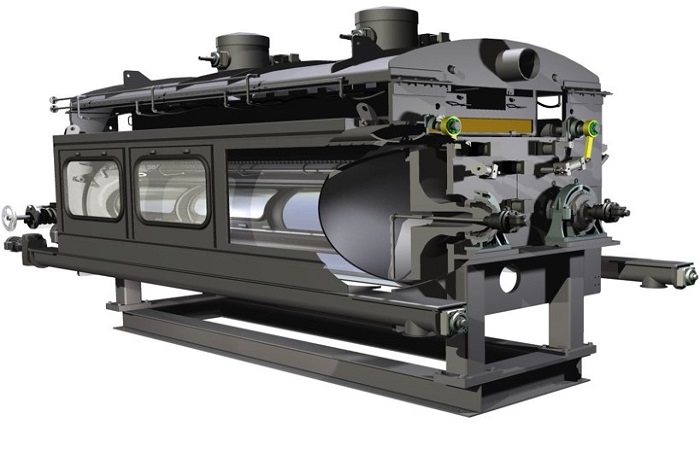

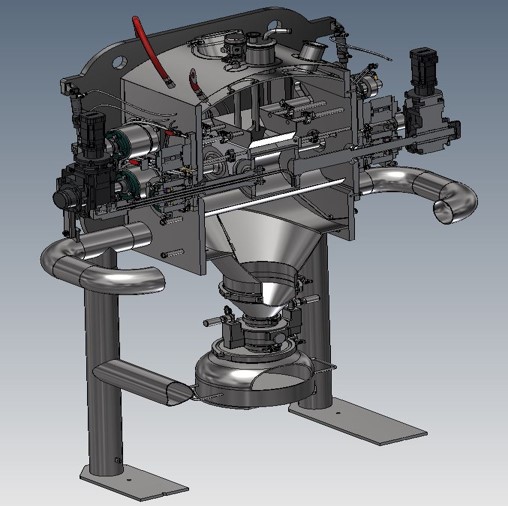

Single Drum Dryer

Manufactured by Hebeler Process Solutions, USA

Single Drum Dryers utilize thin film continuous drying via conductive heat transfer with the addition of multiple applicator rolls to permit drying of successive layers of fresh material, which eliminates void areas and increases the bulk density of the final dried product.

It consists of one rotating saturated steam pressurized center drum and multiple rotating, water cooled or non- cooled applicator rolls spaced around the periphery of the drum. The rotating applicator rolls eliminate void areas; permit drying between successive layers of fresh material to form the product sheet gradually resulting in a product sheet of uniform thickness, density and minimum dusting tendencies.

Single Drum Dryers are highly effective for drying high viscosity liquids or pasty materials such as potatoes, starches, gelatins, adhesives and synthetic resins with high drying efficiency, low operating cost and long term operational reliability.

Due to the hundreds of various types of products and operating environments, almost all aspects of a drum dryer’s mechanical design, operating components and ancillary equipment can be customized to meet each individual process design needs.

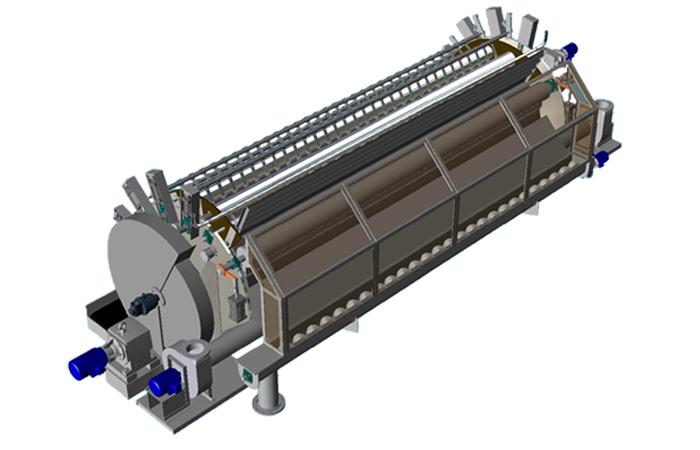

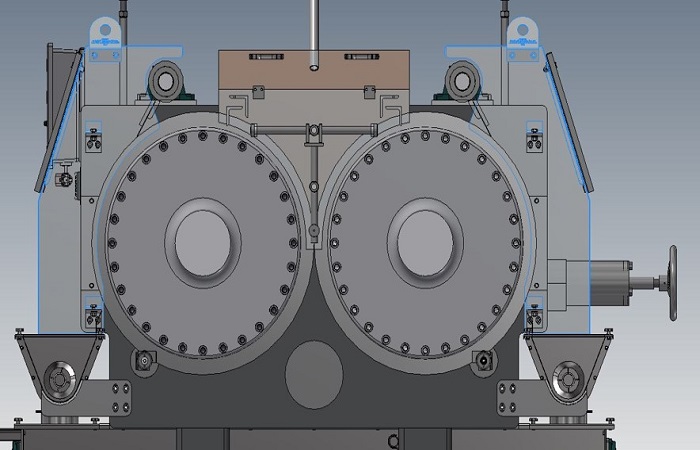

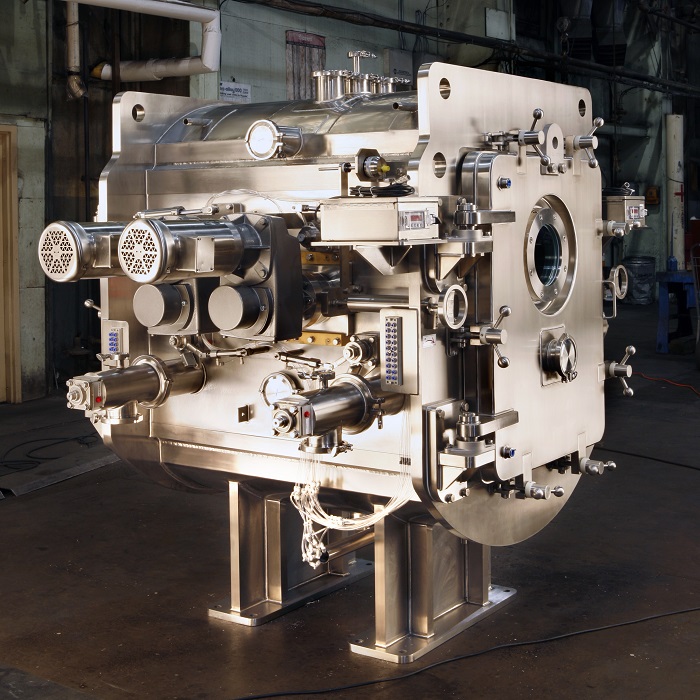

Double Drum Dryer

Manufactured by Hebeler Process Solutions, USA

Utilizing thin film continuous drying via conductive heat transfer, this dryer is used to dry hundreds of various types of food, chemical, environmental, and pharmaceutical materials of widely varying densities and viscosities.

It consists of two rotating saturated steam pressurized drums, one fixed and one adjustable to permit complete control of product film thickness. This requires the drums to be machined to exacting tolerances with perfectly matched lengths. Standard drums can be constructed of cast iron or fabricated steel which comply with current ASME or PED Pressure Code Directives.

Non-standard drums can be supplied to conform to other national design and construction codes.

Atmospheric Double Drum Dryers are the most versatile and widely applied type of drum dryers because of their product versatility, high drying efficiency, low operating cost and long term operational reliability.

Due to the hundreds of various types of products and operating environments, almost all aspects of a drum dryer’s mechanical design, operating components and ancillary equipment can be customized to meet each individual process design needs.

Atmospheric Double Drum Dryers Applications

- Indirect drying – no product contact with heating medium

- Products that will adhere to heated surfaces

- Products that can be compressed

- Heat sensitive as well as non-heat sensitive products

- Solvent removal

- Homogeneous products

- Continuous operation

- All process industries – nutraceuticals, foods, chemicals, energy, environmental, pollution control

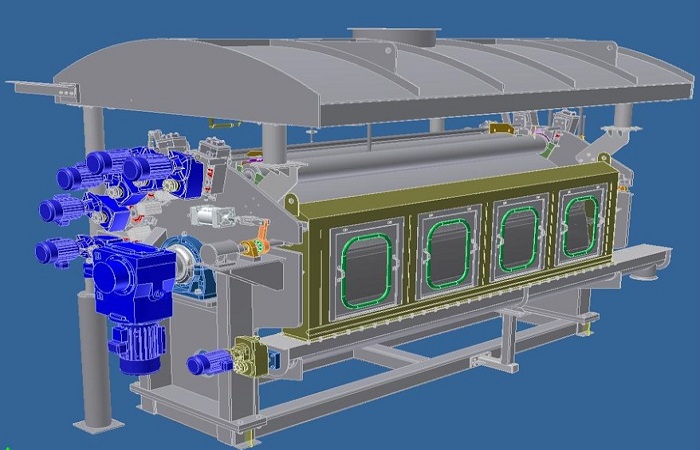

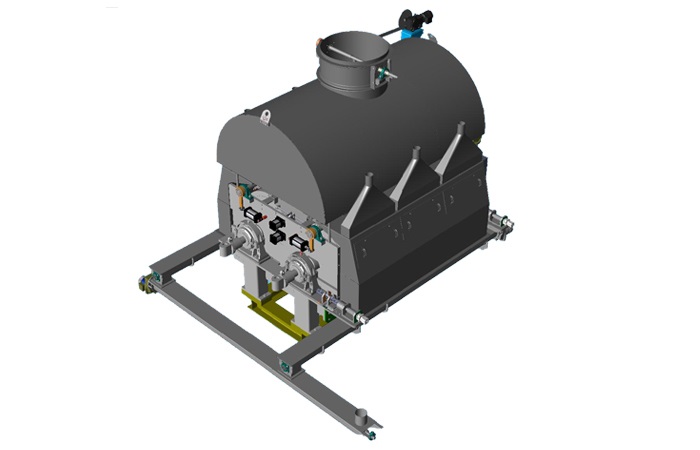

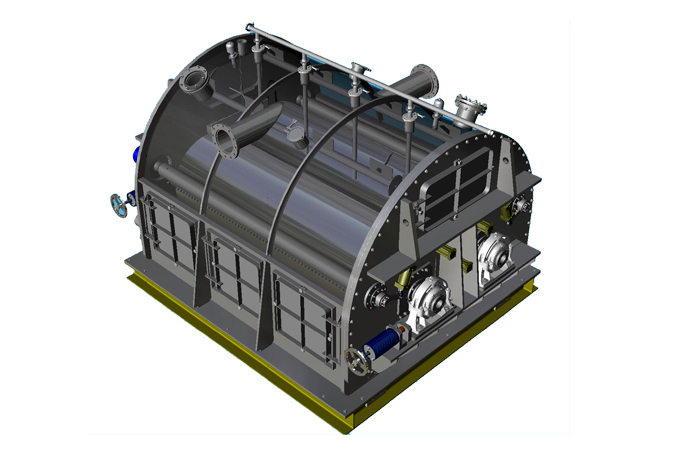

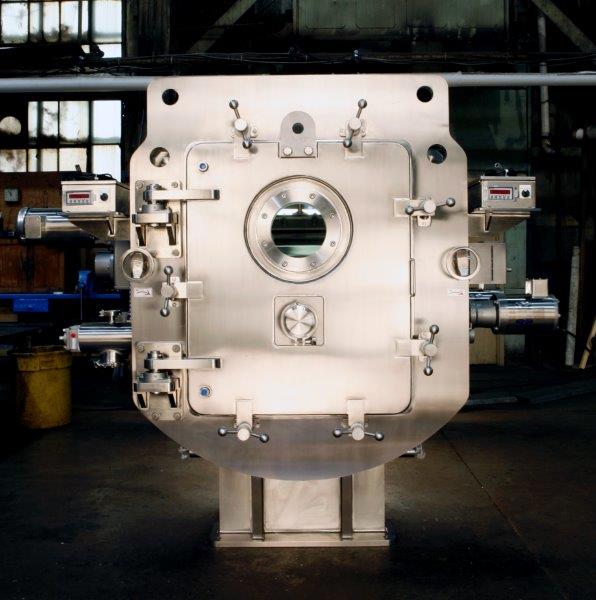

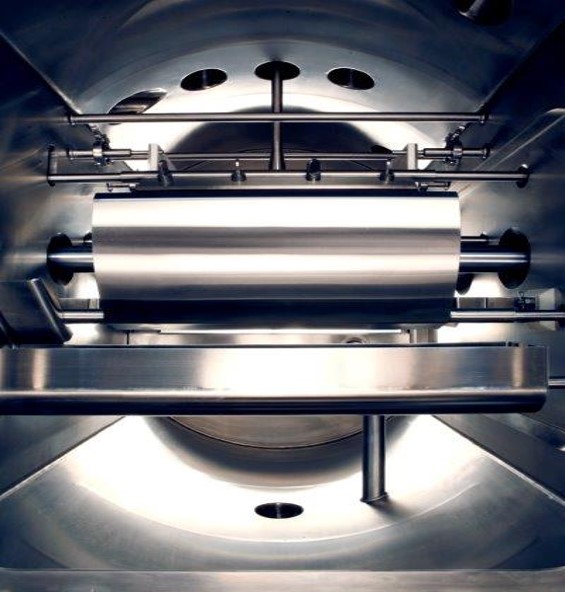

Vacuum Double Drum Dryer

Manufactured by Hebeler Process Solutions, USA

Vacuum Double Drum Dryers are specified when products require uniform low-temperature drying, non-reactive atmospheric drying or complete solvent isolation and recovery drying.

Utilizing thin film drying via conductive heat transfer under vacuum, these dryers can be designed to meet the most stringent sterile operating environments and are particularly suited for pharmaceuticals, nutraceuticals, vitamin extracts, specialty food items, fine chemicals and solvent reclamation of widely varying densities and viscosities.

Depending upon the application vacuum drum dryers can be designed for batch operation, which requires the chamber to be returned to atmospheric pressure to remove the dried product, or continuous operation, which allows the dried product to be removed from the chamber while under vacuum by utilizing several unique air-lock systems.

Due to the hundreds of various types of products and demands of inducing and controlling a vacuum environment, almost all aspects of a drum dryer’s mechanical design, operating components and ancillary support equipment can be customized to meet each individual process design needs.

Our Vacuum Double Drum Dryers are also installed and used for production of HPAPI – High Potency Active Pharmaceutical Ingredient.

These installations in HPAPI require a specialized containment to ensure that employees and their environment are protected from direct exposure to the pharmaceutical ingredients.

Contact Us