Buflovak Vacuum Pan and Kettle Dryers

Manufactured by Hebeler Process Solutions, USA

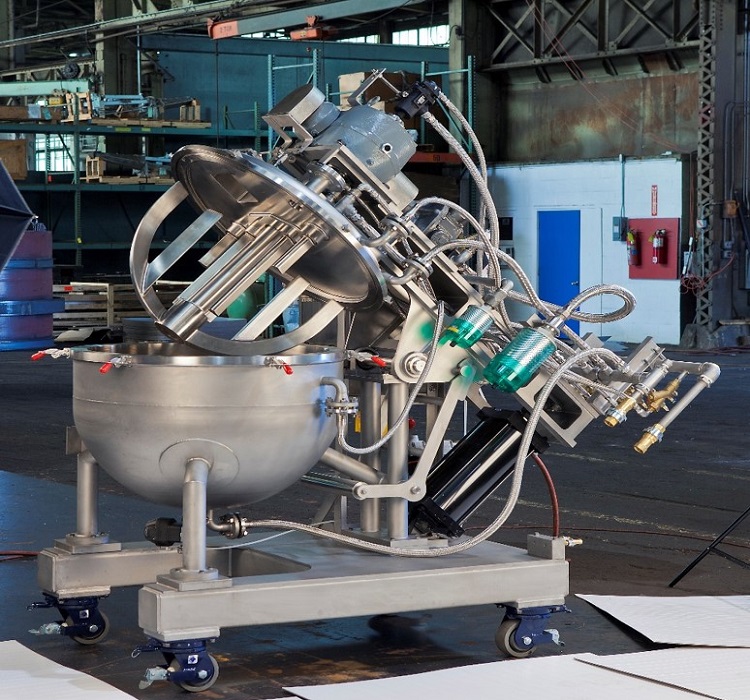

Vacuum Pan Dryers are highly versatile and can be configured to combine a number of process operations in one unit without removing and exposing the product to atmosphere. These process operations consist of one or more of the following: filtering the product, drying the product under vacuum, cooling the product under an inert environment, distilling under reflux, and recovery of solvents.

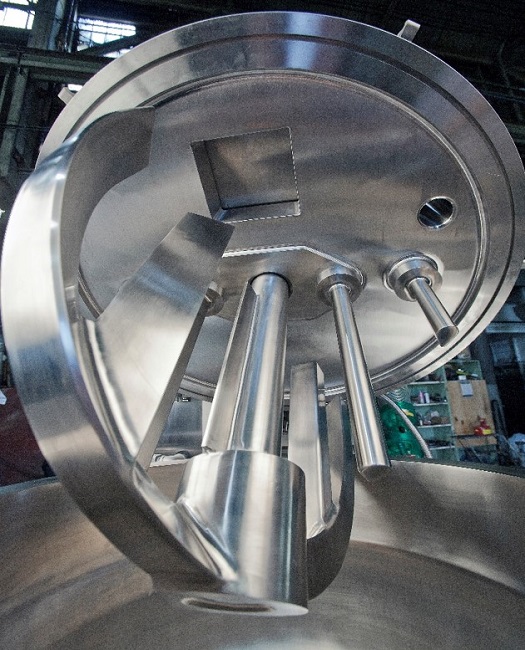

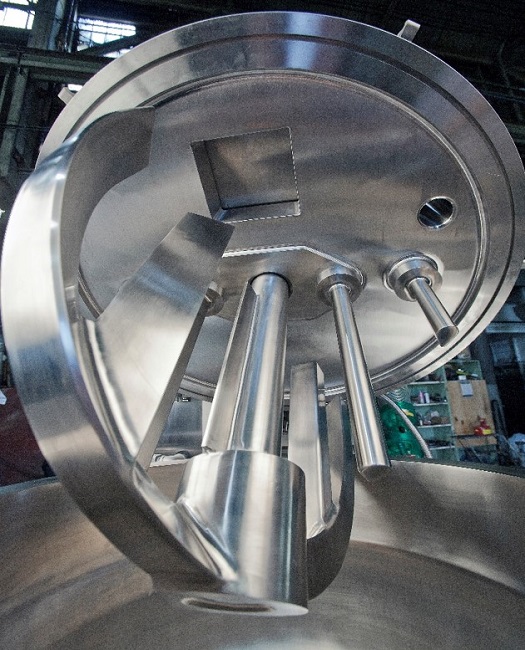

It consists of a stationary vertical jacketed cylinder with flat or curved bottom, dished top and internal rotating custom-select agitator to mix and circulate various materials in the shortest possible processing time.

The batch operation of the vacuum pan dryer is simplified by automatically loading (charging) the wet product into the top of the jacket cylinder with the agitator rotating for uniform distribution and complete dry product discharge through a pneumatically operated side discharge door.

The stationary jacket cylinder and internal chamber are designed to meet the operating pressures and material compatibility requirements for each individual application and are built to comply with ASME, PED Pressure Codes or other national design and construction codes.

Due to hundreds of various types of products and demands of inducing and controlling a vacuum environment, almost all aspects of a vacuum pan dryer’s mechanical design, operating components and ancillary support equipment can be customized to meet each individual process design needs.

Vacuum pan dryers consist of an enclosed flat bottom pan with a jacket to heat or cool of the bottom plate and sides. A vertical agitator thoroughly mixes and circulates the product within the pan.

Vacuum kettle dryers consist of a curved bottom with a jacket to heat or cool of the bottom and sides. A vertical agitator thoroughly mixes and circulates the product within the kettle.