Wyssmont Turbo Dryer

Manufactured by Wyssmont Inc, USA

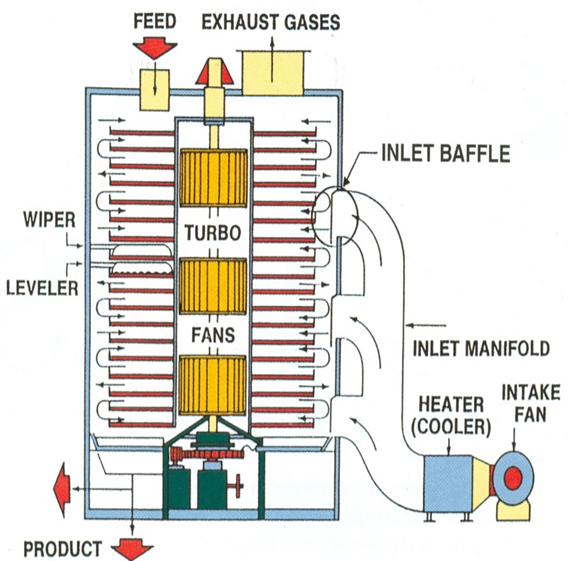

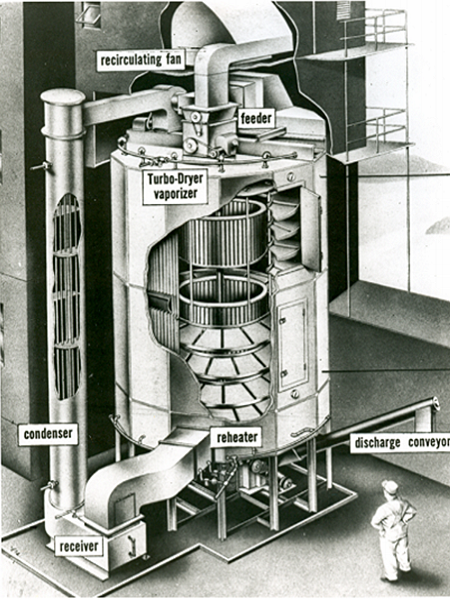

The TURBO-DRYER® by Wyssmont consists of a stack of slowly rotating circular trays. Material is fed onto the top tray. After one revolution, the material is wiped onto the next lower tray, where it is mixed, leveled, and wiped to the next tray after one revolution. This process is repeated on each tray after one revolution. They trays are contained in an enclosure in which heated air or gas is circulated.

This delivers very uniformly dried product because material is intermittently redistributed with plugflow operation. Because of the uniform inside temperature or zoned temperature regions, the turbo-dryer has the closest product temperature control of any dryer possible.

Because of the gentle handling very little dust or fines are created, even with fragile materials such as crystals.

The turbo-dryer handles temperatures up to 600°C with precisely controlled temperature and residence time at easily adjusted and automatically maintained drying conditions.

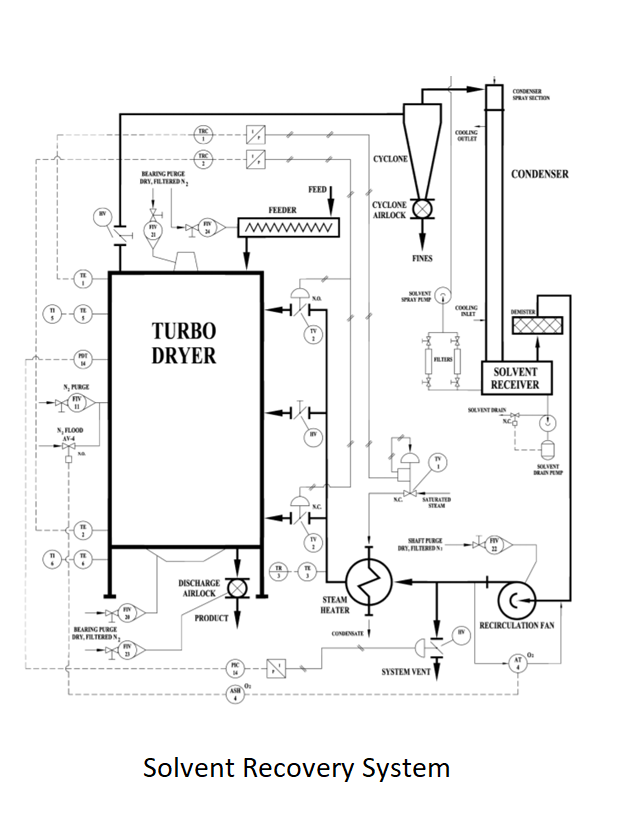

It can operate with inert atmosphere recirculation with solvent recovery but operates also as a dryer, reactor, heat treater, calciner, humidifier, agglomerator, sublimer, roaster, or in combination if required.

The self-cleaning wiping action often eliminates the need for manual cleaning at product changeovers.

The turbo-dryer is easy to startup and operate on different materials and has low maintenance costs because of its unparalleled reliability. Also it has low energy costs (using heat recovery) and low labor costs.

Wyssmont Turbo Dryer - Unique Features

- Handles temperatures up to 600°C (1100°F)

- Precisely controlled temperature and residence time

- Easily adjusted and automatically maintained drying conditions

- Can automatically adjust to varying feed rates

- Can operate with inert atmosphere recirculation with solvent recovery

- Operates as a dryer, reactor, heat treater, calciner, humidifier, agglomerator, sublimer, roaster, in combination if required

- Environmentally sealed, and explosion-proof models

- The self-cleaning wiping action often eliminates the need for manual cleaning at product changeovers

- Easy startup and operation on different materials

- Low maintenance costs because of its unparalleled reliability

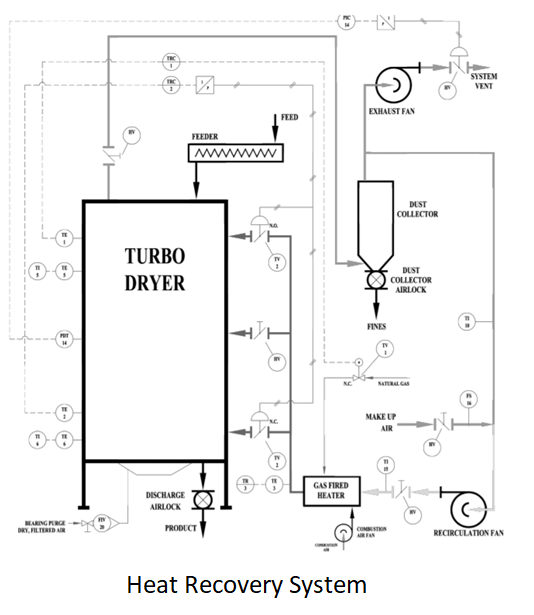

- Low energy costs (using heat recovery, see drawing). Low labor costs

- Can use any heating medium: steam, gas, electricity, oil, high temperature oil or waste gas from other operations

- Low temperature drying as low as 15.5°C (60°F) without vacuum or up to 600°C (1100°F)

- Available in laboratory sizes, package units, and large field erected sizes

- Manufactured in a wide range of materials

- Vertical construction, little space requirements. Outdoor or indoor installations

- Accurate scale-up from tests on a few pounds

Wyssmont Turbo Dryer - Materials Handled

- Powder

- Pastes

- Crystals, Beads

- Sludges

- Granules

- Slurries

- Chunks

- Solids

- Filter Cakes

- Centrifuge Cakes

- Pellets and Flakes

Wyssmont Turbo Dryer can be used for:

Drying With Heat Recovery

Drying products using heat recovery lowers energy costs. Energy consumption as low as 1,600 Btu/lb of water evaporated is typically achievable; if long retention time or high degrees of product uniformity are necessary in a heating or cooling application.Our units provide a compact, easily operable, reliable answer.

They are especially applicable to heating and cooling very fine powders, with minimum particle size segregation. The units are available in designs up to 1100°F (600°C). Where specific time-temperature histories, gentle handling or treatment in special atmospheres are desired, they provide problem specific solutions.

Drying With Solvent Recovery

Wyssmont is predominant in the field of drying with solvent recovery. Compared with the batch solvent recovery dryers, which they often replace, these systems are safe, economical and continuous, and require almost no operator attention. Their design is built around the special features of the TURBO-DRYER®, which is uniquely able to operate at atmospheric pressure with inert gas as the drying medium in a closed system. These systems have a reputation for safety and reliability. Many customers with broad experience in drying equipment will consider only Wyssmont systems when drying with solvent recovery. The TURBO-DRYER® consists of a stack of slowly rotating circular trays. Material is fed onto the top tray. After one revolution the material is wiped onto the next lower tray where it is mixed, leveled, and then after one revolution, wiped to the next tray where the operation is repeated. The trays are contained in an enclosure in which heated air or gas is circulated by internal fans.

Auxillaries

Rotoscoop® Feeder

Our Rotoscoop® Feeder is the only non-plugging airlock feeder. It is excellent for feeding a wet material into a dryer, especially when the dryer is driving off solvent or there is an inert atmosphere in the dryer. Another application is to use it to feed dry solids into a reaction vessel where one of the reaction products is water vapor. The water vapor tends to rise to the top of the vessel and condense on the underside of an airlock feeder plugging it by condensing on the solids in the feeder. The Rotoscoop® Feeder eliminates this problem. It normally operates for 1- 2 years and longer without shutdown for any reason.

Lumpbreakers

1. Rotocage®

Our Lumpbreakers are known for breaking friable product while making very little dust, if any. The

Rotocage® produces a uniform product usually one (1) mm or less without screens and finer with a

screen. The cutting blade design rotor has been used to give uniform length extrudate and is excellent

for scrolled polymer peeled off a drum dryer.

2. RCBP Rotocage®

The RCBP Rotocage® is used for breaking up agglomerates of plastic pellets without damaging them or

fusing. It is particularly apt for screen oversize material that consists of agglomerates. It is available in a

sanitary design, which opens up for easy cleaning.

3. Triskelion®

The Triskelion® breaks large chunks into small chunks without grinding and making fines. Its blades cut

the product rather than crush it. Crushing causes fines formation. Fines tend to blow away or get onto

personnel and into the surroundings. One design enables slabs of a product like a tray dryer product to

be uniformly broken up. Both the Triskelion® and the Rotocage® Lumpbreakers are available for

handling wet material.

4. Cake-Breaker™ feeder

The Cake-Breaker™ feeder acts as both a lumpbreaker and a feeder. It is particularly suited for breaking

up cake from plate and frame filters and friable material. With plate and frame filters, it can be

mechanized on rails to deliver the product to a conveyor alongside the plate and frame filter.

Additional auxiliaries are Vane-Rotor® Airlocks whose rectangular design gives maximum throughput for minimum height and are high-temperature airlocks suitable to 1,000°F and our Multiple Screw Feeder which is designed to give a uniform feed.

Our tip-up chute offers a safe easy way to break up agglomerated contents of 50# bags into a free- flowing, easily-handled product without dust by using a Rotocage® Lumpbreaker.