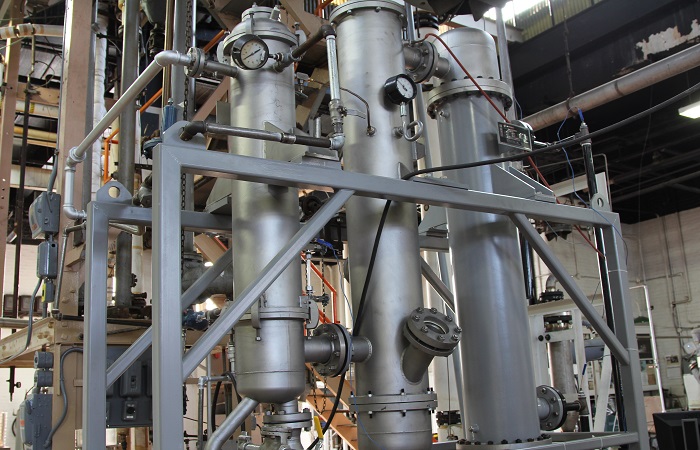

Buflovak Falling Film Evaporator

Manufactured by Hebeler Process Solutions, USA

Falling Film Evaporators offer distinct operating advantages to concentrate many materials,

such as certain food products, fruit juices, pharmaceuticals and similar materials,

which are particularly suited to evaporation in this type of equipment.

Our Falling Film Evaporators are unique as they utilize a novel operating principle from other types.

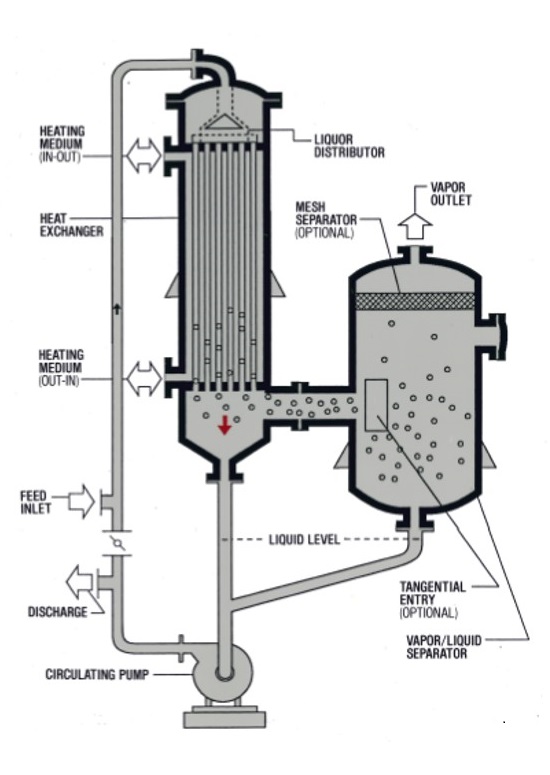

The dilute liquid is fed to the top of the tubes,which flows downward as evaporation occurs.

Uniform distribution of the liquid to the tubes is assured by an exclusive feature which controls the flow of the liquid to the top of the vertical heating tubes. The liquid flows over the edge of the tubes and runs down the inside surface in a thin, uniform film. The vapor travels down the tubes in the same direction as the liquid, gaining in velocity by the addition of more vapor as the mixture descends, resulting in high velocity for both the liquid and vapor.

Falling Film Evaporator Characteristics

- Flexible in operation, permitting continuous or batch operation

- Very suitable for multiple effects

- Simplicity of construction permits economical use of corrosion resistant materials

- Handles liquids which increase in viscosity at higher concentrations because the liquid flows as a thin film down the surface of the heating tubes

- Vaporizes viscous materials more readily than a natural circulation evaporation as vaporization takes place from a thin film

- Can be used advantageously with Thermal Re-compression

- Low power requirements

- Low holding volume

- Can be configured as a counter current falling film for stripping application

Falling Film Evaporator Product Application

- Liquids too viscous for natural circulation

- Liquids where retention time must be minimized

- Heat-sensitive liquids or when excess temperature is critical

- Liquids requiring limited temperature difference

Falling Film Evaporator Application Examples

- Caustic Soda

- Pectin Solutions

- Sorbitol

- Fruit Juices

- Pharmaceuticals

- Sucrose